Time:2025-07-12 11:32:02

Browse:618

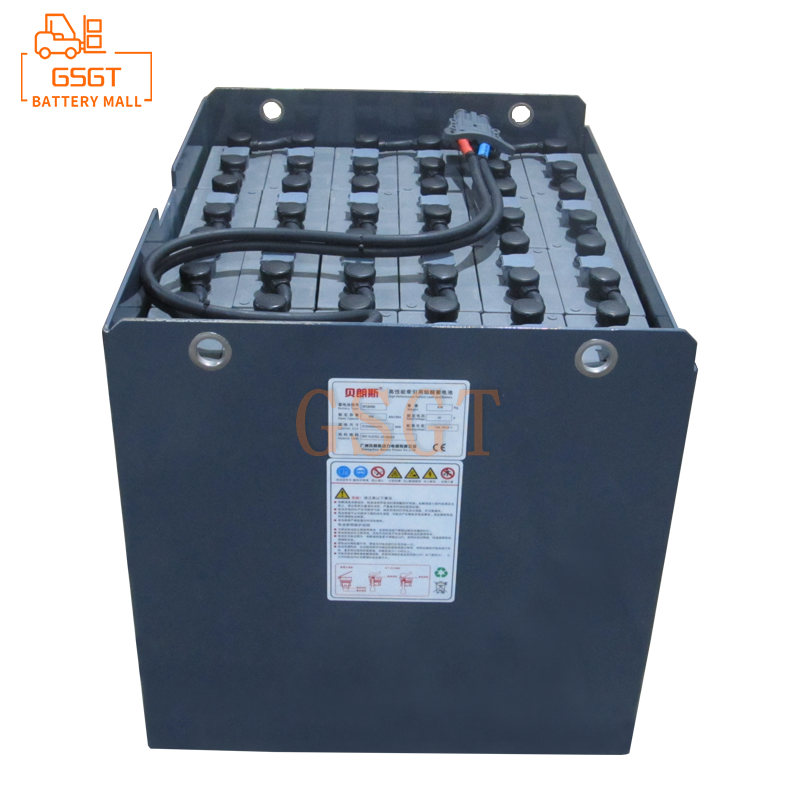

As an important handling equipment in industrial production, the lead-acid battery of a forklift is like the "heart", providing power for its normal operation. However, during long-term use, lead-acid batteries are bound to encounter various malfunctions, which can affect the working efficiency of forklifts. Understanding these common faults and their solutions is crucial for ensuring the normal operation of forklifts.

The battery is discharged.

Phenomenon

When the battery is discharged, the forklift has difficulty starting, or even fails to start at all. Electrical devices such as lights and horns also cannot work properly. During driving, the power was significantly insufficient and the speed was slow.

Reason

The forklift has not been used for a long time and the battery has not been recharged, resulting in natural loss of power.

Charging system malfunctions, such as damaged chargers or poor contact of charging lines, prevent the battery from receiving sufficient power.

There is a leakage in the circuit. Even if the forklift is not in use, the battery is still discharging continuously.

Solution

If the battery is discharged due to long-term non-use, you should first check whether the charger is working properly. Connect the charger properly and recharge the battery. Generally, the charging time is 8 to 12 hours until the battery is fully charged.

Check the charging circuit to see if it is loose or broken, and ensure that the connection of the charging circuit is good. If the charger is damaged, a new one should be replaced in time.

For circuit leakage problems, a multimeter can be used to detect the current in the circuit, identify the leakage point and carry out repairs. After the repair, charge the battery again.

Plate vulcanization

Phenomenon

Plate sulfation will significantly reduce the capacity of the battery. During charging, the voltage rises rapidly and soon reaches the charging termination voltage, but the actual charge is not fully charged. The voltage drops rapidly during discharge, making it impossible to provide a stable power supply continuously.

Reason

Long-term insufficient charging leads to the active substances on the plates not being fully transformed, gradually forming sulfides.

The electrolyte level is too low, exposing the upper part of the plates to the air, where it reacts with oxygen to form a sulfide layer.

If the electrolyte concentration is too high or impure, it will accelerate the sulfidation process of the plates.

Solution

For slightly sulfated storage batteries, overcharging can be adopted. First, completely discharge the battery. Then, charge it at half the normal charging current. When a large number of bubbles appear in the electrolyte and the voltage and electrolyte density stabilize, continue charging for 2 to 3 hours.

If sulfation is severe, the electrolyte in the battery can be poured out, distilled water added, and then charged with a small current for a long time to gradually dissolve the sulfides. After that, pour out the distilled water, add the electrolyte of the standard concentration again, and then charge normally.

To determine whether the plates have sulfated, it can be determined by measuring the terminal voltage of the battery and the density of the electrolyte. During the charging and discharging processes, if the changes in voltage and density are abnormal and do not conform to the normal rules, it is very likely that the plates are sulfated.

Leakage

Phenomenon

When a battery leaks, traces of electrolyte can be found around the battery casing. In severe cases, electrolyte may drip down. Leakage not only corrodes the components around the battery but also reduces the performance of the storage battery.

Reason

The battery case was subjected to external forces such as collision and compression, causing the case to crack.

The sealing glue aged and cracked, causing the electrolyte to seep out from around the terminal post.

Severe wear or corrosion of the terminal posts leads to poor sealing and leakage.

Solution

If the shell is cracked, minor cracks can be repaired with epoxy resin adhesive. If the crack is large or the casing is severely damaged, the battery casing needs to be replaced.

For leakage caused by the aging of sealing glue, the old sealing glue can be removed thoroughly, new sealing glue can be reapplied, and curing treatment can be carried out.

When the terminal post leaks, first clean the surface of the terminal post thoroughly. If the wear on the terminal post is not severe, apply sealant for sealing. If the wear is severe, the terminal posts need to be replaced.

Q&A session

Question: What should I do if the battery gets very hot during charging?

Answer: Severe heating during battery charging may be caused by a variety of reasons. If the charging current is too large, check whether the output current of the charger meets the requirements of the battery. If not, a suitable charger needs to be replaced. If there is a short circuit fault inside the battery, the battery should be disassembled for inspection and repair to eliminate the short circuit point. In addition, if the amount of electrolyte is insufficient, it may also cause heating during charging. At this time, distilled water should be added to the specified liquid level height. During the charging process, pay close attention to the battery's temperature. If the temperature exceeds 45℃, charging should be suspended and resumed only after the temperature drops.

Question: How to prevent sulfation of the plates?

Answer: To prevent sulfation of the plates, it is necessary to do a good job in daily maintenance. First of all, it is necessary to charge the battery regularly to ensure that it is fully charged and avoid being in a state of insufficient charging for a long time. Secondly, it is necessary to frequently check the liquid level of the electrolyte to ensure that it is 10-15mm higher than the plates. If the liquid level is too low, distilled water should be added in a timely manner. In addition, to prevent the electrolyte concentration from being too high, the electrolyte should be prepared in accordance with the prescribed proportion. At the same time, try to avoid leaving the battery idle for a long time. If it needs to be stored for a long time, the battery should be fully charged first and replenished regularly.

By understanding the common faults of forklift lead-acid batteries and their solutions, and doing a good job in daily maintenance and care, the service life of the battery can be effectively extended to ensure the normal operation of the forklift. In actual operation, if you encounter more complex faults, it is recommended to seek the help of professional maintenance personnel to avoid greater losses.

$3130

$3920

$3060

$1630

MESSAGE

Professional And Efficient

Security

Affordable Price

Professional Services