Time:2025-07-19 09:49:06

Browse:596

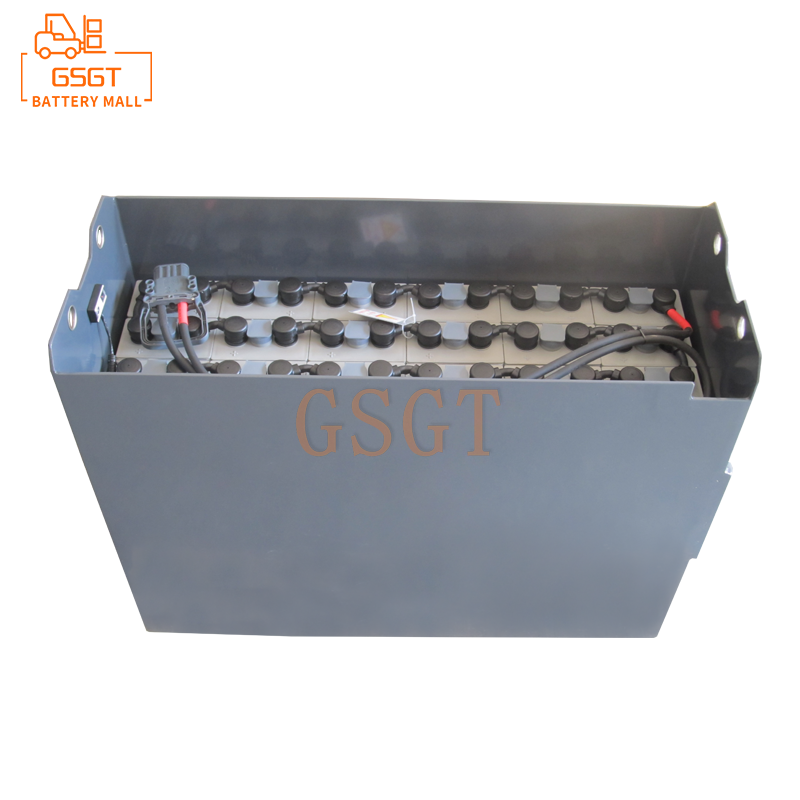

In the bustling industrial plant area, forklifts shuttle back and forth, providing powerful impetus for material handling. As the "heart" of forklifts, the performance of lead-acid batteries directly affects the operational efficiency and cost of forklifts. Nowadays, the shortcomings of traditional lead-acid batteries in terms of endurance and lifespan are gradually emerging, and innovative and practical designs have become the key to breakthroughs in the industry.

Innovative breakthrough in battery life

Endurance is one of the core performances of lead-acid batteries in forklifts, directly affecting the continuous operation time of forklifts. Traditional lead-acid batteries often struggle to meet the demands of long-term and high-intensity operations due to issues such as insufficient active material on the plates and inadequate chemical reactions during electrolysis.

To solve this difficult problem, the R&D personnel made bold innovations in the plate material. The adoption of a new type of multi-element alloy plate, which is scientifically proportioned from various elements such as lead, calcium and tin, not only enhances the mechanical strength of the plate but also increases the adhesion capacity of active substances. Compared with traditional plates, the utilization rate of active materials in the new multi-alloy plates has increased by more than 20%, significantly enhancing the battery capacity.

At the same time, the electrolyte formula was optimized and upgraded. A small amount of rare earth element compounds are added to the traditional sulfuric acid electrolyte to form a specially designed composite electrolyte. This composite electrolyte can accelerate the ion migration speed and promote a more thorough and complete chemical reaction between the plates and the electrolyte. In actual tests, the lead-acid battery with this innovative design has a 30% increase in endurance compared to traditional products, significantly reducing the number of times forklifts need to be charged during operation and improving operational efficiency.

Extended service life design

The service life of lead-acid batteries for forklifts is an important factor affecting the operating costs of enterprises. Traditional batteries often have a short service life due to problems such as sulfation and corrosion of the plates during the charging and discharging process. Frequent battery replacement not only increases the procurement cost but also affects the production progress.

To extend the service life, the innovative design starts from the battery structure and adopts a sealed single-cell series structure. Each individual battery has an independent sealed cavity, which reduces the evaporation and leakage of the electrolyte and avoids mutual interference among individual batteries. This structure also facilitates heat dissipation, reducing the impact of excessively high temperatures on battery life. Through these designs, the service life of forklift lead-acid batteries has been extended by more than 50%, significantly reducing the operating costs of enterprises.

A comprehensive improvement in security

The working environment of forklifts is complex, and the safety of lead-acid batteries is of vital importance. During the use of traditional batteries, there may be safety hazards such as leakage, short circuit and even explosion, which pose a threat to the safety of operators and the factory area.

Innovative design has adopted multiple measures in terms of safety. Firstly, for the battery casing material, high-strength flame-retardant engineering plastics are selected. This material has excellent impact resistance and flame retardancy, effectively preventing leakage and short circuits caused by casing rupture. Secondly, install multiple safety protection devices, including overvoltage protection, overcurrent protection, temperature protection, etc. When the battery malfunctions, the protection device can quickly cut off the circuit to prevent dangerous accidents.

In addition, a leak-proof diversion structure is set up inside the battery. Even if there is a small amount of leakage, the electrolyte can be guided to a dedicated collection container through the diversion trough to prevent the electrolyte from corroding forklift components and polluting the environment.

Q&A session

Question: What impact does the innovative and practical design of lead-acid batteries for forklifts have on the operating costs of forklifts?

Answer: Innovative design can reduce the operating costs of forklifts in multiple aspects. In terms of battery life, enhancing the battery life reduces the number of charges, saves charging time, increases the effective operation time of forklifts, and indirectly lowers the time cost. In terms of service life, extending battery life reduces the frequency of replacement, lowers the procurement cost of batteries and the labor cost during replacement. In terms of safety, the occurrence of safety accidents has been reduced, avoiding economic losses caused by equipment damage and casualties due to accidents. Overall, innovative and practical designs can significantly reduce the operating costs of forklifts.

Question: What challenges will the innovative design of lead-acid batteries for forklifts encounter in practical applications?

Answer: Innovative design faces some challenges in practical application. The first challenge is the maturity of technology. Some new materials and technologies perform well in laboratory Settings, but some problems may arise in large-scale production and practical applications, which require continuous optimization and improvement. Secondly, there is the cost challenge. The adoption of new materials and advanced technologies will increase the production cost of batteries, which may lead to a rise in product prices and affect market acceptance. The last challenge is user acceptance. Some operators are accustomed to the traditional battery usage and maintenance methods and may have a resistant attitude towards innovative battery designs. Training and guidance are needed to help users gradually accept and adapt to them.

Summary

The innovative and practical design of lead-acid batteries for forklifts is an inevitable trend in the industry's development. Its breakthroughs in terms of endurance, service life and safety have brought significant benefits to industrial production. Although there are still some challenges in practical applications, with the continuous advancement of technology and the gradual recognition of the market, these problems will be gradually solved. In the future, with the development of industrial intelligence and automation, the innovative design of lead-acid batteries for forklifts will move towards greater efficiency, environmental friendliness and intelligence, providing stronger impetus for the development of the industrial sector.

$2040

$800

$850

$880

MESSAGE

Professional And Efficient

Security

Affordable Price

Professional Services